Company History

• FIRST to develop DRY ICE BLASTING EQUIPMENT in India (Through their Principal Biz Partners – UEW)

• One of India’s largest DRY ICE BLASTING EQUIPMENT EXPORTER

• Manufactures Dry Ice Equipment designed to use 3mm Dry Ice Pellets & Block Dry Ice.

• Tested for different applications

• Have been in the Dry Ice Cleaning Service business since 200

What is Dry Ice?

• Frozen carbon dioxide -78.5C

• CO2 comprises approx 0.03% of the atmosphere

• By-product of ammonia, alcohol/brewing, and ethanol

• Also natural wells (volcano)

• No new carbon dioxide created by Dry Ice usage

Dry Ice is frozen carbon dioxide, a normal part of our earth’s atmosphere. It is the gas that we exhale during breathing and the gas that plants use in photosynthesis. It is also the same gas commonly added to water to make soda water. This gas is often captured during industrial processes and recycled to make Dry Ice.

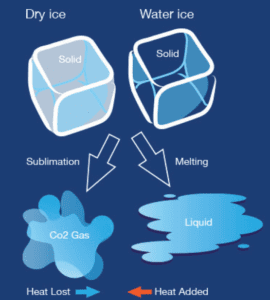

Dry Ice is particularly useful for freezing, and keeping things frozen because of its very cold temperature: -109.3°F or -78.5°C. Dry Ice is widely used because it is simple to freeze and easy to handle using insulated gloves. Dry Ice changes directly from a solid to a gas – sublimation in normal atmospheric conditions without going through a wet liquid stage. Therefore it gets the name “dry ice”. As a general rule, Dry Ice will sublimate at a rate of five to ten pounds every 24 hours in a typical ice chest. This sublimation continues from the time of purchase; therefore, pick up Dry Ice as close to the time needed as possible. Bring an ice chest or some other insulated container to hold the Dry Ice and slow the sublimation rate. Dry Ice sublimates faster than regular ice melts but will extend the life of regular ice.

Dry Ice was first observed in 1835 by French inventor Adrien-Jean-Pierre Thilorier (1790–1844), who published the first account of the substance. In his experiments, it was noted that when opening the lid of a large cylinder containing liquid carbon dioxide, most of the liquid carbon dioxide quickly evaporated. This left only solid dry ice in the container. In 1924, Thomas B. Slate applied for a US patent to sell dry ice commercially. Subsequently, he became the first to make dry ice successful as an industry. In 1925, this solid form of CO2 was trademarked by the DryIce Corporation of America as “Dry ice”, leading to its common name. That same year the DryIce Co. sold the substance commercially for the first time, marketing it for refrigeration purposes.

What are Dry Ice Pellets?

Dry Ice is typically produced in three standard forms: large blocks, cylindrical small (5/8 or 1/2 inch diameter) pellets and cylindrical tiny (1/8 inch diameter), high surface to volume pellets that float on oil or water and do not stick to the skin because of their high radii of curvature. Tiny dry ice pellets are used primarily for ice blasting, quick freezing, fire fighting, oil solidifying and have been found to be safe for middle school student gloves on and safety glasses on experiments. A standard block weighing approximately 30 kg, covered in taped paper wrapping is most common. These are commonly used in shipping, because they sublime relatively slowly due to a low ratio of surface area to volume. Pellets are around 1 cm (0.4 in) in diameter and can be bagged easily. This form is suited to small-scale use, for example at grocery stores and laboratories where it is stored in a thickly insulated chest.

3mm Dry Ice Pellets offer a lower temperature than water ice, longer holding times and require no clean-up. Due to these unique properties, it has a wide variety of commercial uses in several different industries.

What is Dry Ice Blasting?

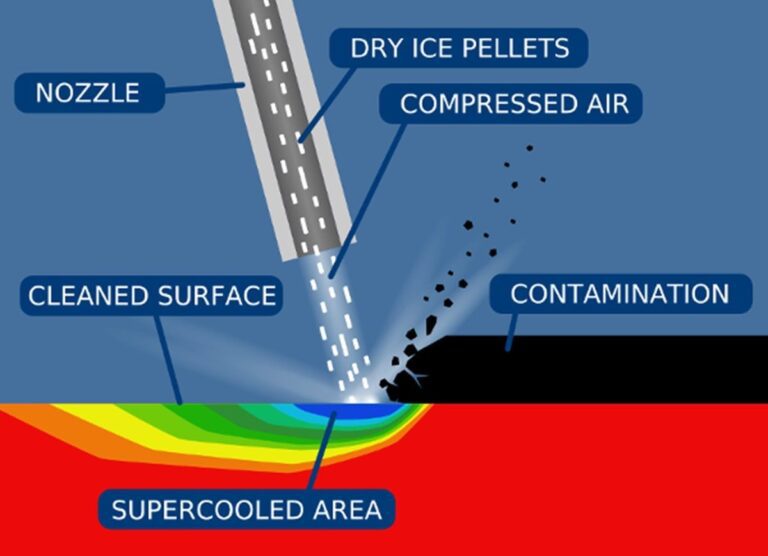

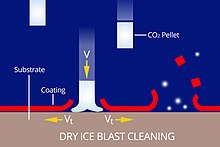

It is a process in which particles of dry ice are propelled with high-velocity air (usually at 6 – 12 bar air pressure) to impact and clean a surface. Disrupting the cleaning industry, dry ice blasting is an innovative solution that gives you stellar cleanliness for your machines. Using carbon dioxide in the form of dry ice as the cleaning agent, in place of conventional media like chemicals or water, this method is revolutionizing. The process blasts dry ice pellets onto the machine that freezes any accumulated dirt and oil residue. The cold temperature causes the dirt to crack, leaving a clean machine behind. Safe, efficient and effective, eliminates dirt easily.

The Best Way to Deep Clean

Machines

Benefits of Dry Ice Blasting

New technology breeds new phrases – “Cleaner Clean”

Unlike all other surface preparation technologies, there are:

• 100% free of water

• Not Abrasive

• No Secondary Waste

There is NO other environmentally safer alternative.

Rapid Cleaning Time

Traditional machine cleaning techniques can take hours leading to an unnecessarily prolonged downtime. No prolonged downtime needed, because Cryotech's cleaning solutions take just under 20 minutes!

Complete Machine Preservation

A non-destructive approach to safely cleaning your machine, dry ice blasting is a completely waterless, chemical-free and heatless process. Being 100% moisture-free, it ensures that any electrical wires and electrical circuits remain preserved.

100% Sustainable & EPA-Approved

Our dry ice blasting method for automotive machine cleaning is EPA-approved and leaves behind no secondary waste like water, shampoo, cleaning agents, etc.

Efficient

Leading edge dry ice blasting is a safe, and risk-free machines deep cleaning solution. This zero-waste, quick-freezing medium reaches the most inaccessible corners, leaving behind nothing more than a clean machine.

Cost Effective

The process uses a combination of pressurized air and dry ice to clean your machine, while the low consumption of blasting material means it is cost-effective and time saving too.